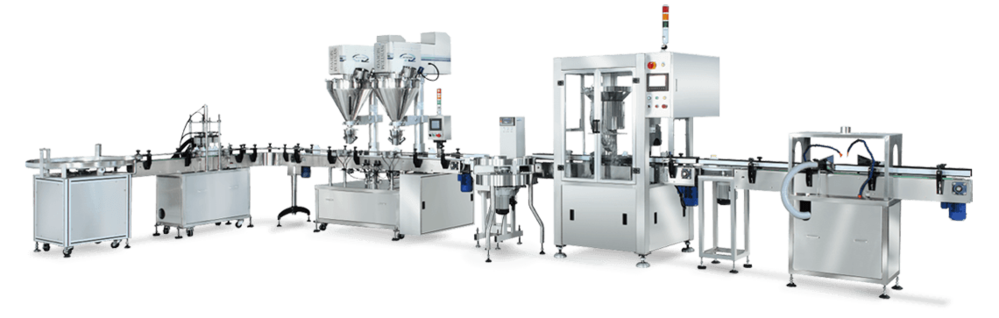

A filling system that can integrate with the systems of bottle/can lead in, air-cleaning, powder filling, spoon filling, weight measurement, auto capping, and auto labeling... etc

Model :

CYP-BPL

| Production line | Power Bottling line |

| Filling Rang |

Filling

Rang:300-3000 g (Need to change the screw) |

| Capacity | Depends on the filling volume and bottle shape |

Press-close type sealing mechanism by air

operated for ensuring smooth appearance of product without pin-hole problem.

No material exists at sealing position that assures superior tightness of

sealing.

Printing point photocell sensor is easy to adjust for eliminating waste of packaging film. Or simply input packaging length for the same purpose.

Minimum sealing temperature variation. Employ PID calculation to maintain temperature tolerance within ±2˚C.

Self-diagnostic function. Whenever there’s an error occurs, such as no packaging film, no color tape, photocell sensor error, excessive or under sealing temperature or air pressure failure... etc, the machine will stop automatically, and the screen will display the problem points and trouble-shooting instructions.

Nitrogen gas filling device is available to be added on for allowing the oxygen existing in product to be controlled within fewer than 2%.

Strip packaging is available.

Transmission system of the filling machine is driven by Japan Mitsubishi servo motor for high accuracy and stability.

10 sets of memory modules for memorizing different kinds of products and filling weights.

HMI touch screen for operational control.

All air cylinders employ Japan (SMC) for dependable quality and stability.

Japan Mitsubishi PLC.

Material storage tank is 14L. (Available to connect with a material supply system.)

Printing point photocell sensor is easy to adjust for eliminating waste of packaging film. Or simply input packaging length for the same purpose.

Minimum sealing temperature variation. Employ PID calculation to maintain temperature tolerance within ±2˚C.

Self-diagnostic function. Whenever there’s an error occurs, such as no packaging film, no color tape, photocell sensor error, excessive or under sealing temperature or air pressure failure... etc, the machine will stop automatically, and the screen will display the problem points and trouble-shooting instructions.

Nitrogen gas filling device is available to be added on for allowing the oxygen existing in product to be controlled within fewer than 2%.

Strip packaging is available.

Transmission system of the filling machine is driven by Japan Mitsubishi servo motor for high accuracy and stability.

10 sets of memory modules for memorizing different kinds of products and filling weights.

HMI touch screen for operational control.

All air cylinders employ Japan (SMC) for dependable quality and stability.

Japan Mitsubishi PLC.

Material storage tank is 14L. (Available to connect with a material supply system.)

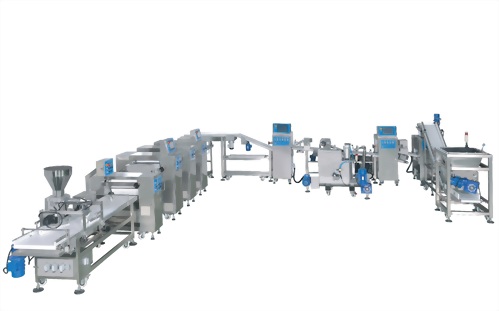

Designed for metering and filling various types of bottled/canned powder and granular products, such as, canned milk powder, Chinese / Western medicine powder, food powder and chemical powder... etc