Our CYP-IM9 design for producing teff injera with high capacity.

For injera factories seeking consistent texture and scalable output, CYP‑IM9 delivers 120+ pieces/hour based on a 3‑minute bake time, simulating traditional flavor with industrial reliability.

| Model | CYP-IM6 | CYP-IM9 | |

| Machine Type |

High Capacity Auto Teff Injera maker |

High Capacity Auto Teff Injera maker | |

| Capacity |

Max. 90pcs/H(based on baking time 3 mins) |

Max. 120pcs/H(based on baking time 3 mins) | |

| Mold Quantity | 6 sets | 9 sets | |

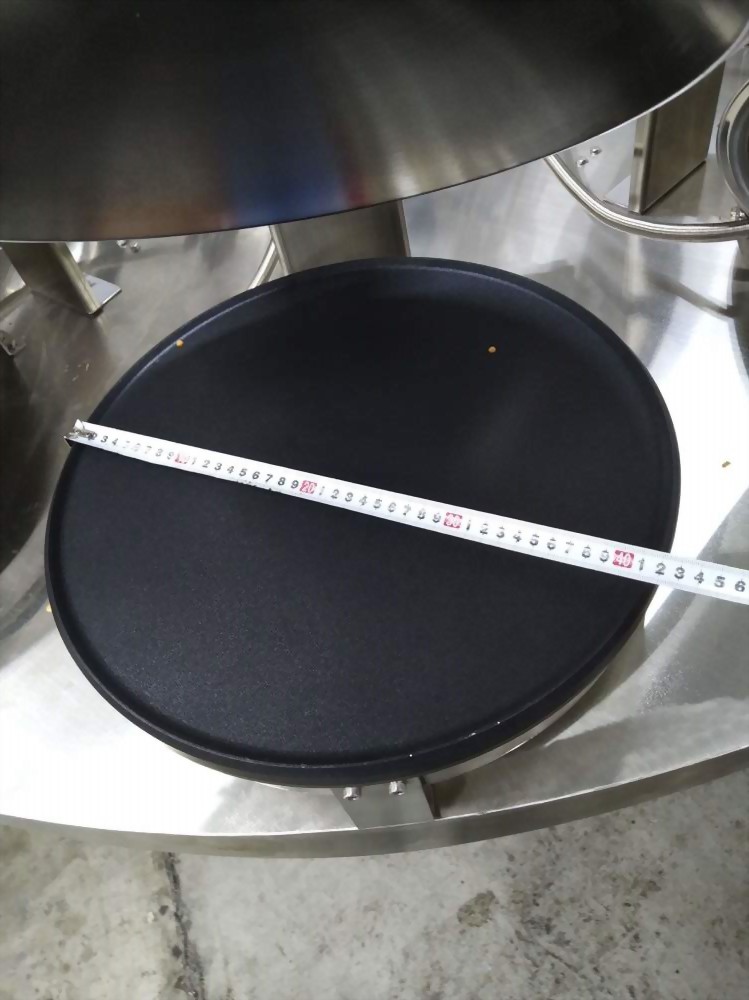

| Mold Size |

Dia. 400~500mm |

Dia. 400~500mm | |

| Temp. Range |

0-399℃ |

0-399℃ | |

| Speed |

Adjustable |

Adjustable | |

| Tank Size | 13L |

13L |

|

| Machine Size |

W1,900 x D1,750 x H1,300mm |

W2,300 x D2,100 x H1,300mm |

|

| Power |

3 phase 380V/220V 13,200w |

3 phase 380V/220 19,800w |

|

1. Highlight Production Efficiency

Injera factories typically deal with bulk orders, so emphasize:

Hourly output: “Capable of producing up to 120~240 injera per hour based on a 2~3-minutes bake cycle.”

Daily volume: “Up to 960~1,920 pcs injera in a standard 8-hour shift with minimal operator intervention.”

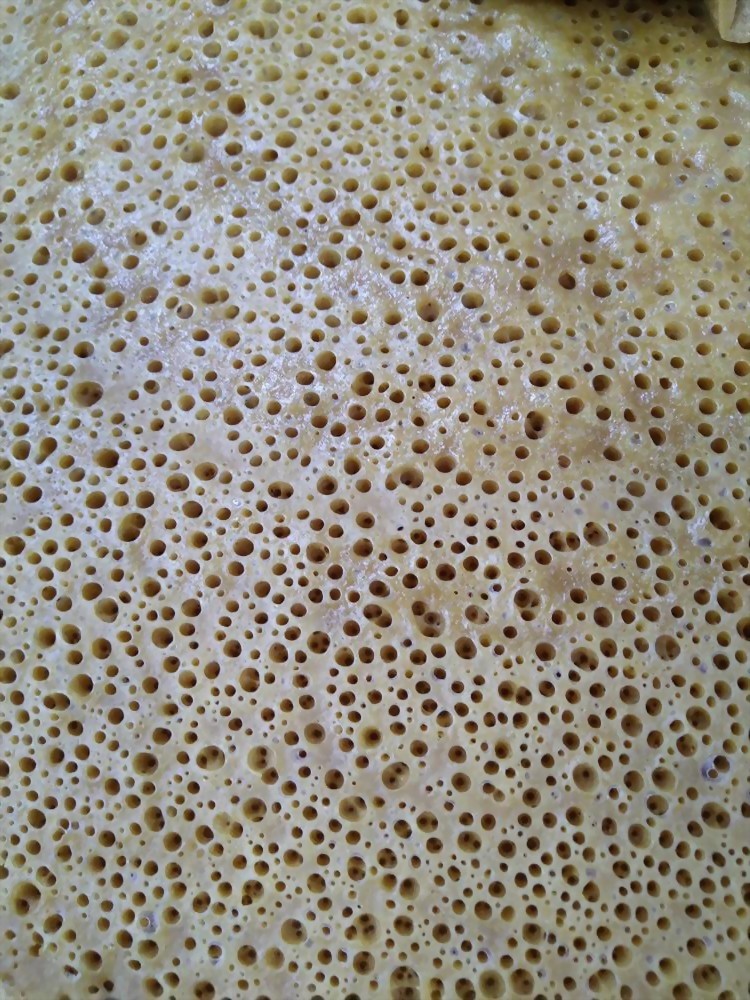

Batch consistency: “Ensures even browning, diameter uniformity, and eyes texture with every batch.”

2. Address Traditional Flavor and Texture Concerns

Many injera makers worry about automation compromising authenticity.

Include a section like:

Preserve the Traditional Taste — With Modern Consistency

“Our system uses an even heat distribution plate and gentle batter spreader to replicate the traditional ‘eyes’ and texture that injera is known for. You can maintain the look, taste, and softness your customers expect—now at industrial scale.”

3. Feature Ease of Cleaning and Food Safety

Injera batter is wet and sticky—cleaning is a major issue.

Include:

“All machine parts in contact with batter are made from food-grade stainless steel.”

“Easy to disassemble and wash—reducing downtime and meeting hygiene standards.”

“Designed to comply with international safety and food processing regulations, including CE”

4. Automated Refill System

Injera factories often deal with large tanks of batter. Mention:

“Optional automatic batter refill system available to support uninterrupted operation.”

“Reduce operator fatigue and manual refilling.”

5. Customization for Factory Layout

Factories vary in size and line flow.

“CYP‑IM9 can be integrated into existing production lines or installed as a standalone unit.”

“We provide CAD layout assistance for optimal workflow and space usage.”

6. True case

“A commercial injera producer in Chicago was able to triple their output while reducing labor by 60%—after switching from semi-manual pans to the CYP‑IM9 system.”

7. Add Technical Specifications Table

Clearly display things like:

Specification Detail

Output Rate 120~240 pieces/hour

Heating Type Electric

Plate Diameter 40cm/50cm

Power Consumption [3 phase 380V/220 19,800w]

Material SUS304 Stainless Steel And Anodic aluminum alloy

Optional Add-ons Automatic refill system, cooling conveyor

8. We can help

“ Request a factory quotation”

“Download full machine specification PDF”

“Watch demo injera maker video : https://www.youtube.com/watch?v=wnaR5JMypo4”

“Book a consultation with our automation team by cypmt.chris@gmail.com”

✅ Injera Export Facilities

Support continuous production for bulk export orders

Maintain consistent quality across thousands of pieces daily

Meet international standards for hygiene and consistency (CSA, CE-compatible)

✅ Local Ethnic Food Manufacturers

Serve growing demand from Ethiopian, Eritrean, and East African communities globally

Reduce reliance on skilled manual labor for flipping or timing

Perfect for bakeries supplying restaurants, supermarkets, or cultural festivals

✅ Frozen Injera Production Lines

Integrates easily with freezing, packaging, and labeling lines

Maintains texture and “eyes” post-reheating due to even baking

✅ OEM or Private Label Producers

Efficient for high-volume B2B contracts under white-label distribution

The pouolar size of diameter 40cm and 50cm plates are ready for you

Programmable controls ensure repeatable results across batches

✅ New Factory Startups

Ideal for entrepreneurs entering the ethnic or health food markets

Lower operational complexity means less training time

Space-saving circular layout fits most factory floor plans